Composite Mould Release Liners/Teflon Breathable Fabric/Teflon Release Fabric/Composite Mould Release Teflon Fabric/Wind Turbine Mould Release Liner/Wind Turbine Blade Peel Ply Teflon Fabric/Black Anti-static Teflon Fabric/Porous Teflon Release Fabric/Non-Porous Teflon Release Fabric/Mould Release Fabric/Teflon Release Fabric In Vacuum Bag/Wind Turbine Mould Vacuum Bag Teflon Release Fabric/PTFE Mould Relase Fabric/Teflon Oven Linner/PTFE Toast Oven Paper/PTFE Baking Sheet/BBQ Grill Mat

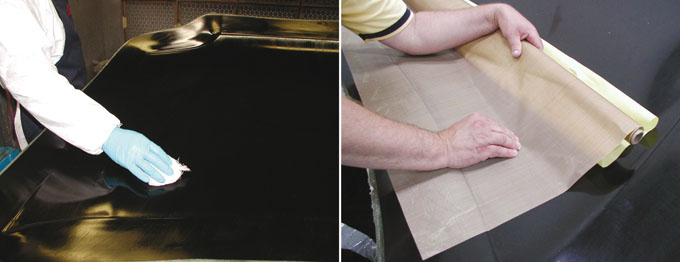

An important component used in the moulding of composite objects is the material used to line the mould tool. Mould liners, also referred to as mould releases or release liners, protect the mould from the resins used and ideally enable a quick and clean release of the moulded product from the mould/release liner.

For less complex shapes, PTFE coated fabric serves as an effective mould release. Where mould tools are more complex, adhesive fabrics or tapes are used to prevent shifting.

In both fabric and tape mould release applications, the base fabric is generally PTFE coated fiberglass. For tapes, pressure sensitive silicone adhesive allows easy application, a sure grip, and quick and clean release. For best results, the grade of fabric and thickness/grade of PTFE should be based on the demands of the job.

Our standard mould release material is PTFE Coated Fiberglass Tape (3 mil, 5 mil, and 6 mil) which is a tape with pressure-sensitive adhesive that will conform and remain in place easier than a coated fabric. Depending on the application, different grades, offer varying degrees of finish and durability for multiple uses.

Once the resin and composite material has been filled into the mould, the curing process follows. When the product has cured, the PTFE fabric/tape allows for clean release from the tooling and the composite part is now complete.

PTFE Coated Fiberglass Fabric/Tape is best suited for this application due to its high heat and abrasion resistance which is effective during the curing stage. Exceptional release characteristics allow the composite product to release cleanly from the mould.

1. What are our advantage to start business with you ?

(1) Prompt delivery. We have six big coating machines and some other small machines.

The delivery time is about 5-15 days.

(2) Reasonable price. Our machines are imported, which can improve the work efficiency,

thus we can provide you high quality with competitive price.

(3) Variety choices. Our products are divided into economical series and premium series.

We can fulfill a variety of requirements for you and bring best benefits for each other.

2. Do you have a good material stock for quick delivers ?

We have a good material stock for quick delivers. Every time we produce a large amount,

we will produce more than the specific quantity. For these products, we can sell to our small distributors for the quick order.

3. How wide is your standard production in PTFE fiberglass fabric ?

The standard width is 1250mm. The max width is 3850mm.The min width is 1000mm.

We can also provide you the customized items if required.

4. What about the MOQ ?

For the regular thickness and width, we can provide you any quantity you need.

5. What about the raw material you use ?

We use imported fiberglass from Taiwan and the PTFE resin is imported from Daikin and DuPont.

6. Do you have the specific QC department ?

Of course we have the specific QC department.Our company applies strict quality control system and service system.

7. What about the warranty?

We are quite confident in our products.We have special quality control department who will 100% check each

goods before shipment,and we can assure you all the goods sent out are in good conditions.When customers

receive the goods in 15 days,if,unfortunately,there occurs broken ones,please tell us and show us the detailed proof

so we can check it and give certain replacement in the next order.

8. How to order samples?

We can provide FREE samples,but you need to afford the freight.If you place an order next time,we will return the samples freight to you.